Meet our most suitable implimentations that will meet your performance and cost transformation needs in production.

At Smart Coore, we analyze our customers’ needs in the most accurate way and carry out an uninterrupted project process until their needs are fully met. Thus, we offer our customers both software and hardware solutions for sensors and reading and machine management in topics such as solutions that reduce production costs, traceability, sustainability and efficient production.

Data Collection and Display Devices

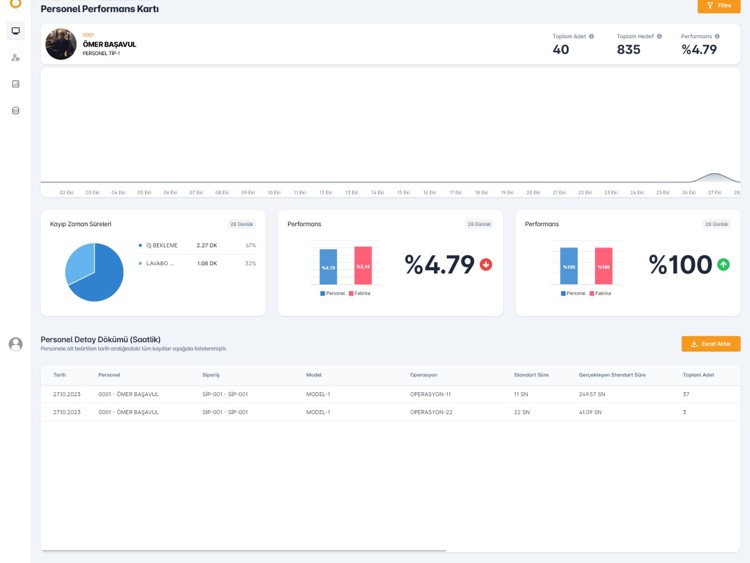

You can achieve a minimum 10% – maximum 35% increase in efficiency with our electronic meters, which measure and display the performance at your production points on a quantity-target-yield basis. You can perform instant live monitoring thanks to the display at the production point, light warnings, information screens, parameter settings and error-free and uninterrupted data flow.

Production Management Software Application

Android Tablet Applications

Our tablet applications, which can be redesigned as desired, such as providing work order flows according to your company’s needs, reporting product features, recording manufactured product controls, ensure the end of paper processes in the field. With the production tracking feature, you can perform measurement, authorization, information and monitoring operations at the same time.

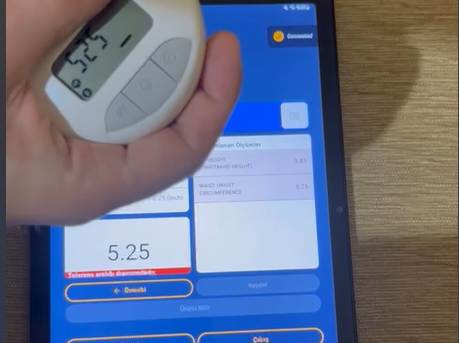

Smart Tape Measure Application

You can carry out the measuring tape and recording of the results in your control processes completely electronically and wirelessly. You can reduce your costs with time savings of up to 70% and have a more accurate analysis.

PLC Digitalization Solutions

By digitalizing the controls of the machines you manage with the PLC in your production line and providing authorizations from a single center, we minimize the error rate and make the processes controllable, analysable, and reportable.

Sensor and RFID Solutions

We can track and transfer the data you measure by working integrated with the sensors, RFID tags and tunnel stations on your machines. With our wired/wireless communication solutions, you can access distances in your production area from a single center.